Double Girder Gantry Crane

- 5t

- 10t

- 16t

- 30t

- 50t

- 60t

- 100t

- A3

- A4

- A5

- A6

- A7

- A8

-

Lifting hook

Lifting hook

- Product Overview

- Application Scenario

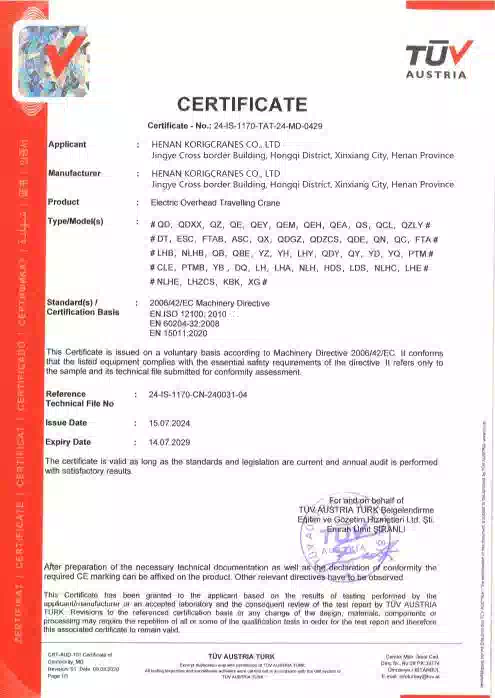

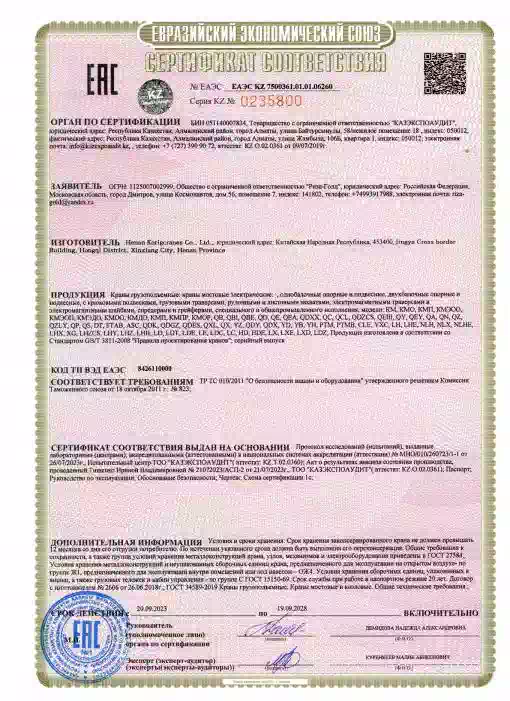

- Certificate

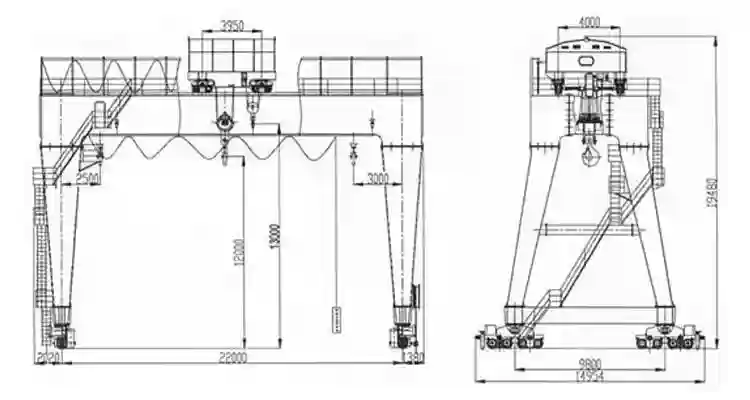

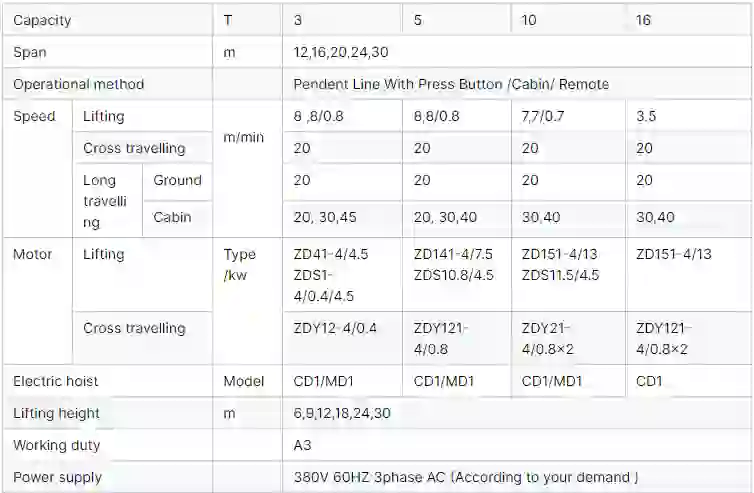

For gantry crane for sale, the Type MG double girder gantry crane – including large gantry crane models – is composed of gantry, crane crab, trolley traveling mechanism, cab and electric control system. The gantry features a box-shape structure, with the track positioned at the side of each girder, and the leg can be divided into type A and type U according to user’s requirements.

Double Girder Gantry Crane

The control method could be ground control, remote control, cabin control or a combination of these; in the cab, there are adjustable seats, insulating mats on the floor, toughened glass for the windows, fire extinguishers, electric fans, and auxiliary equipment such as air conditioners, acoustic alarms and interphones, which can be furnished as required by users.

Process of Korig Double Girder Gantry Crane:

1. CNC cutting of girder web plate with high deflection accuracy.

2. Shot-blasting Sa2.5 for whole girder treatment after welding with stress release.

3. Epoxy zinc rich coating and painting with thickness 2x2 with 140μm.

4. 10.9 class bolts connect girders and legs.

5. Three-in-one motor reducer with vertical gear motor driving.

6. Motors with high protection class IP55, F class, 40% ED.

7. End carriage is equipped with anti-friction bearings, cellular rubber buffers, and derailment protectors.